Precision Textiles has launched a patent-pending liquid-crystal polymer (LCP)-fortified fire-resistant filler cloth designed to help mattress manufacturers compete in today’s fast-moving roll-packed market. The new material meets the upcoming 2026 New York flammability requirements and complies with California AB 2998 chemical restrictions.

Industry-Driven Innovation

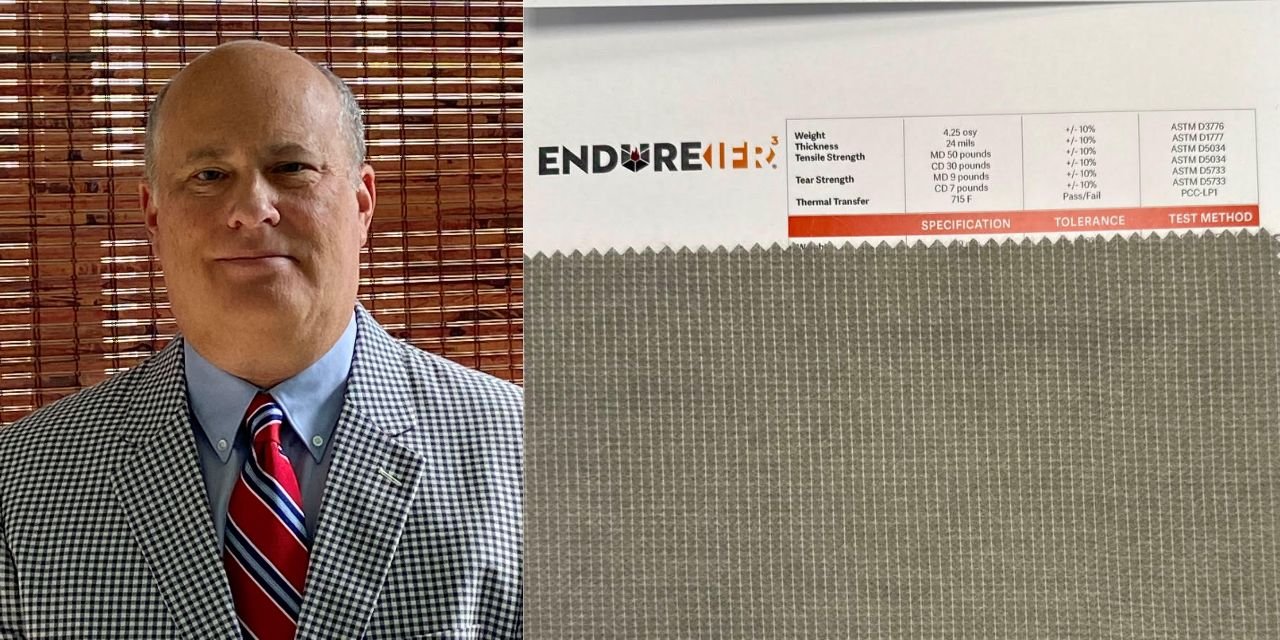

The company created this next-generation bottom-panel barrier as part of its Endure line. By integrating LCP technology—used in aerospace, protective gear, and other high-stress applications—Precision Textiles delivers superior tensile strength, improved fire resistance, and greater structural stability.

This innovation directly responds to the manufacturing pressures of roll-packed mattress production and long-distance shipping.

Meeting Real-World Manufacturing Challenges

“After extensive conversations with our customers, we saw the need for a bottom panel that could handle the realities of roll-packed production,” said Gerry Welkley, National Sales Manager, Precision Textiles. “We built this material from the fiber level up to meet those demands. It gives manufacturers stronger protection without adding complexity to their process.”

Advanced FR Barrier Performance

The LCP-Fortified Filler Cloth marks a major leap in FR barrier design. Precision Textiles engineered it using a proprietary mix of high-performance fibers and a specialized char-forming finish. The material withstands the mechanical stress of hybrid roll-packed mattresses while maintaining stability under heavy compression and heat.

Strength, Stability, and Heat Protection

Designed specifically for roll-packed mattresses, the filler cloth offers exceptional tensile and tear strength, tolerating the torque generated when pocket-coil hybrid mattresses are compressed, rolled, and boxed.

Its char shield, made from LCP fibers and a micro-clay coating, forms a dense, crack-free char layer that blocks molten foam from dripping through during fire events. The result keeps peak heat release under 200 kW in 16 CFR 1633 testing.

The material’s low thermal shrinkage also ensures bottom seams stay intact after heat exposure.

Ready for Evolving Safety Standards

The new filler cloth fully meets 2026 NY flammability regulations and current California AB 2998 requirements. This gives manufacturers a bottom-panel barrier that supports compliance as safety and chemical-restriction rules continue to evolve.