Abstract: Plasma technology is an emerging area of research for textile processing that offers numerous benefits in terms of fabric modification, functionalization, and finishing. This paper provides an overview of plasma technology and its various applications in textile processing. The paper covers the fundamentals of plasma technology, the different types of plasma, and the techniques used for generating and applying plasma. The paper also reviews recent research and development in plasma technology for textile processing, including the functionalization of textiles, the modification of textile surfaces, and the use of plasma for dyeing and finishing.

Introduction:

The textile industry is constantly searching for new and innovative ways to modify, functionalize, and finish textiles. Plasma technology is an emerging area of research that offers a range of benefits for textile processing, including improved adhesion, reduced water, and chemical usage, and improved dyeing and finishing properties. This paper provides an overview of plasma technology and its applications in textile processing.

Fundamentals of Plasma Technology:

Plasma is an ionized gas that is created by applying energy to a gas, typically through the use of electrical fields. The energy breaks down the gas into its constituent ions, electrons, and free radicals, creating a reactive environment that can be used for a variety of chemical reactions. The different types of plasmas include low-pressure, atmospheric pressure, and surface plasmas, each with its unique advantages and disadvantages.

Generating and Applying Plasma:

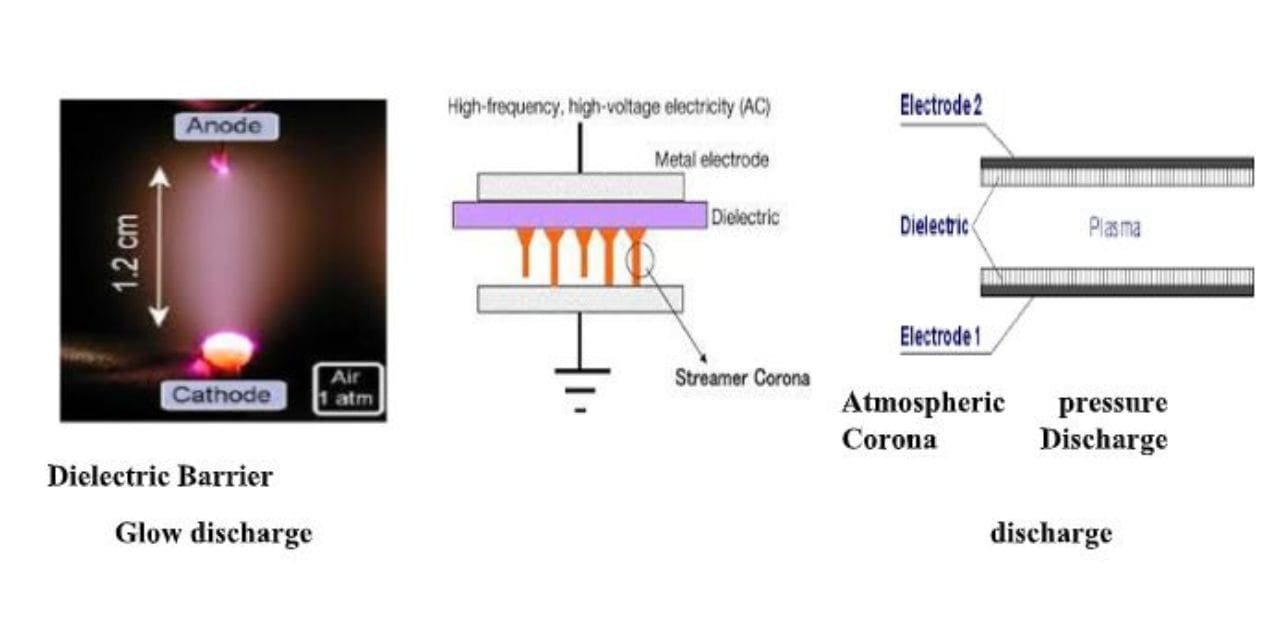

There are several techniques used to generate and apply plasma to textile surfaces, including atmospheric pressure plasma jet, corona discharge, dielectric barrier discharge, and microwave plasma. Each of these techniques has its advantages and disadvantages and can be used for different textile applications.

Plasma Technology for Textile Processing:

Plasma technology has numerous applications in textile processing, including the functionalization of textiles, the modification of textile surfaces, and the use of plasma for dyeing and finishing. The functionalization of textiles involves the introduction of new chemical groups onto the textile surface to improve adhesion, anti-microbial properties, or UV stability. The modification of textile surfaces using plasma includes the creation of surface hydrophilicity or hydrophobicity, improved dyeing and finishing properties. Plasma can also be used for dyeing and finishing, which involves the modification of the textile surface to improve the uptake of dyes or improve the durability of finishing agents.

Recent Research and Development:

Recent research and development in plasma technology for textile processing have focused on the development of new plasma systems and techniques, the optimization of plasma processing conditions, and the evaluation of the functional properties of plasma-treated textiles. For example, researchers have developed plasma systems that can be integrated into textile processing lines, allowing for continuous and efficient plasma treatment of fabrics. Other research has focused on the optimization of plasma processing conditions to achieve the desired functional properties of plasma-treated textiles.

Conclusion:

Plasma technology is an exciting area of research for textile processing that offers numerous benefits for fabric modification, functionalization, and finishing. The different types of plasmas and techniques used to generate and apply plasma offer a wide range of possibilities for textile applications. The research and development in plasma technology for textile processing are ongoing, and the potential for new applications and improvements in processing efficiency and sustainability is high.

References

Yang Chena, Xiaoliang Tang, Baotong Chen a, Gao Qiu, “Atmospheric Pressure Plasma Vapor Treatment of Thermo-sensitive Poly(N-isopropylacrylamide) and Its Application to Textile Materials”, Journal of Fiber Bioengineering & Informatics 4:3 (2011) pp. 285-290.

Shah J.N. and Shah S.R., “Innovative Plasma Technology in Textile Processing: A Step towards Green Environment”, Research Journal of Engineering Sciences, Vol. 2(4), 34-39, April (2013)

http://textilelearner.blogspot.in/2012/04/application-of-plasma-technology-in.html

http://textilelearner.blogspot.in/2013/10/plasma-treatment-in-textiles.html

F. Sadova and E. V. Pankratova, “Low-Temperature Plasma Surface Modification of Textiles Made from Natural Fibers and Advanced Technologies”, Plenary reports from the 5th international symposium on theoretical And applied plasma chemistry, (September 3–8, 2008, Ivanovo, Russia)

Buyle, “Nanoscale finishing of textiles via plasma treatment”, Materials Technology 2009 VOL 24, pp 46-51

R.Shishoo, “Plasma technology for textiles”, The textile institute, Woodhead publishing limited

LEITAT Technological center, “Plasma technology applied to textiles”, T-POT PROJECT 18th June 2009 Terrassa (Spain)

K. Chinta*, S. M. Landage and Sathish Kumar. M, “Plasma technology & Its application in Textile wet Processing”, International Journal of Engineering Research & Technology (IJERT), Vol 1, Issue 22, July 2011

Ms. Anita Desai, “Plasma technology: A review”, The Indian Textile Journal, January 2008 issue.

A newsletter, “Plasma processing update”, Facilitation Centre for Industrial Plasma Technologies, Institute for Plasma Research Issue 56 January – April 2009