Afreen Begum

Bombay Textile Research Association

and

Shital Palaskar

Bombay Textile Research Association

Abstract

Khadi, in contrast to other mill-produced textiles, has served as a testament to India’s history and demonstrates the truth behind the saying that ‘what is old possesses true value.’ Despite facing challenges from competing mill fabrics, Khadi has persevered.

The hand-spinning process of Khadi, which utilises a charkha (spinning wheel) followed by manual weaving on a handloom, sets it apart from conventional mill fabrics. Handloom weaving is not a mere craft; it embodies a lifestyle for countless Indian families, significantly impacting the economy, culture, and promoting sustainable fashion. This distinctive craftsmanship contributes to Khadi’s uniqueness and durability. The creation of Khadi is a highly careful procedure that considers environmental factors from the spinning phase through to the weaving stage. Natural dyes pair effectively with the organic fibres used in Khadi textiles.

Interest in natural dyes is on the rise, even with the challenges of sourcing plant materials, colouring issues, and the need for mordants, emphasising the urgent necessity to adopt herbal dyes in place of synthetic options to protect the environment and the delicate ecosystems we depend on. Textile wet processing commonly involves numerous chemicals, contributing significantly to environmental contamination and potential health hazards for humans. The eco-friendly natural dyeing process of Khadi fabric utilises Rare Earth Metal Salts as mordants, linking it to an innovative natural dyeing technique that employs unconventional mordant salts. This type of mordant, known as rare earth salt (RE salt), is utilised for the very first time in the natural dyeing process. The remarkable binding capacity of the rare earth metal enhances dye absorption. The amount of rare earth mordant needed to achieve the desired outcomes is approximately 60-80% less, compared to the conventional one, which results in a reduced effluent load. Consequently, the combined impact of natural dyes and rare earth mordants paves a path for promising opportunities for the natural dyeing of Khadi textiles.

Keywords – Khadi fabric, Natural dyes, RE salts, Sustainable.

Introduction

Khadi is a tribute to India’s heritage and a prime example of the saying “old is indeed gold,” compared to other mill fabrics. In spite of facing competition from various mill fabrics, Khadi has endured. What sets Khadi apart from mill fabric is its hand-spinning process utilising a charkha (spinning wheel), followed by manual weaving on a handloom. This distinctive method contributes to the uniqueness and durability of Khadi. The khadi production process is highly conscientious, taking environmental factors into account from the spinning stage through to the weaving. At its core, Khadi is a handwoven textile crafted from cotton, silk, or wool. One may envision it as merely a basic piece of fabric, yet in truth, Khadi represents far more. It embodies centuries of heritage and stands as a symbol of India’s struggle for independence. In contrast to contemporary, machine-produced textiles, Khadi is meticulously woven by hand utilising a charkha (spinning wheel). It serves as a testament to how an act as straightforward as spinning cotton can possess the strength to confront an empire. [1]

Figure 1: Charkha (spinning wheel)

Wearing Khadi was more than merely a choice of fabric; it served as a quiet form of protest. It conveyed a powerful message: “We can achieve self-sufficiency. We do not require foreign products.” Khadi’s influence extended beyond the political realm; it ignited a cultural and economic revolution as well. By advocating for Khadi, Gandhiji played a crucial role in reviving the ancient craft of handwoven textiles, which had been gradually fading away under the colonial domination of British rule. The resurgence of Khadi also contributed to the stimulation of the rural economy. As an increasing number of individuals engaged in spinning and weaving, job opportunities were created, empowering rural communities. Khadi was not merely a fabric; it embodied a movement that fostered a sense of connection to one’s heritage. In essence, Khadi symbolised the core of India’s self-sufficiency. By adopting it, we were not only resisting colonialism but also celebrating our traditions, culture, and way of life. Khadi is experiencing a resurgence in the contemporary world.

It is no longer limited to traditional attire; it has evolved into a fashion statement. Indeed, Khadi has become a significant contributor to the sustainable fashion sector. It exemplifies how something classic can harmoniously integrate with modern trends. Currently, designers are reimagining Khadi, incorporating it into stylish, contemporary designs that resonate with modern tastes. Whether it is a fashionable Khadi kurta or a relaxed Khadi shirt, this fabric is increasingly becoming a staple in urban wardrobes. Khadi has seamlessly aligned with the modern world’s rising demand for eco-friendly fashion. In light of the detrimental environmental effects of fast fashion, Khadi presents a sustainable alternative. The hand-weaving process of Khadi consumes minimal energy and is considerably more environmentally friendly than mass-produced textiles. It represents a green revolution that enables us to embrace fashion without compromising the planet. [1,2]

Dyeing with Natural Dyes

The natural fabric of khadi complements natural dyes well. Natural dyes are becoming more and more popular despite the challenges associated with obtaining plant resources, colour flaws, and the necessity for mordants. It is imperative that we switch from synthetic dyes to herbal ones in order to protect the ecosystem and the ecology of our delicate surroundings.

Commercial textile dyeing almost exclusively uses synthetic colourants, which can be harmful to health and in terms of environmental pollution. As a result, natural dyeing, which exhibits better biodegradability and environmental compatibility, is increasingly getting accepted by the industry. However, natural dyes are usually associated with low colour fastness with respect to washing or sunlight. These issues are traditionally overcome with heavy metal salts as mordants such as potassium dichromate, stannous chloride, ferrous sulphate and copper sulphate. They play the role of bridging head between the fabric and the colourant molecule. However, these too have an adverse impact on public health. Therefore, selecting a new mordant to replace the traditional heavy metal salts has been an important part of the development of natural dyeing of textiles. It is in this context that REs, which are eco-friendly and compatible with the environment, have recently attracted attention. It is found that khadi cotton and silk fabrics dyed with natural dyes using RE as mordant exhibited high colour shade stability in varying pH conditions, and it required 8 to 9 times less than conventional mordant to get the desired result.

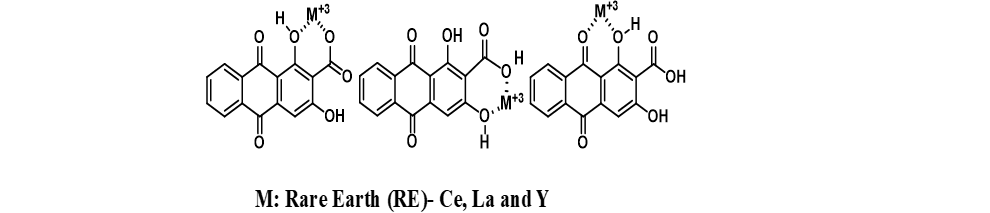

The improved colour fastness to washing, rubbing and light of khadi cotton and silk fabrics dyed with natural extracts using RE mordants is attributed to its ability to form a large number of coordination bonds with amino, hydroxyl or carboxyl group ligands of the natural dye molecules. The interaction of the pigment with the dye molecule and the fabric is very strong due to the following structure formation and forming strong bonds with the rare earth metal ion, as shown in Figure 2. The dye molecules present in natural dyes have appropriately placed chelating oxygen atoms for metal binding. [2,3]

Figure 2: Showing metal chelation with RE ions(M3+)

Procedure of Natural dyeing on Khadi fabric and characterisation of the sample.

The beaker dyeing procedure was followed for the natural dyeing of khadi cotton using different RE salts. The Khadi fabric was introduced into the dye bath at room temperature, and then the temperature of the dye bath was raised at a rate of 2 ◦C per minute to 60 ◦C. At this temperature, the dyeing was continued for 45 min. After that, the temperature of the dyeing bath was rapidly reduced in approximately 15 min. The dyed fabrics were then rinsed under running water until the water was colourless (visual evaluation) and dried at room temperature. [3,4]

The CIELab values of the RE salts mordanted natural dyeing Khadi fabric were analysed and it showed a considerable rise in K/S value from the khadi unmordanted sample. The wash and light fastness also show a better result than the unmordanted samples. Hence, one can conclude that the use of rare earth salts for natural dyeing of khadi does give very good fastness properties of the khadi material. [5,6]

Conclusion

Consequently, the technique of natural dyeing has undergone significant enhancements following the replacement of traditional mordants with RE salts. Three notable improvements were observed: firstly, the new mordants facilitated better dye uptake; secondly, the fastness properties of the dyed samples were enhanced; and thirdly, there was a reduction in wastewater pollution due to the fact that the new RE mordants were used in only a fraction of the original quantity. Therefore, it can be concluded that incorporating RE salts in natural dyeing offers advantages regarding improved colour uptake and better fastness properties. The superior chelation properties of the RE salts with both the dye molecules and khadi fabric account for these benefits.

References:

- Ahsaan, M. (2009, May 27). Khadi-The fabric of Freedom and Fashion. India News Network.

- Padma S. Vankar, Afreen Begum; Natural dyeing of khadi cotton using rare earth salts as mordant with annatto extract. Pigment & Resin Technology 29 November 2024; 53 (6): 1051–1054.

- Gangwar, A.and Vankar, P.S. (2021) Surface modified rare earth mordanted cotton dyed with Eupatorium Extract, BTRA Scan, VolL No 3 page 7-11.

- Gangwar, A.and Vankar, P.S. (2021) Improved Fastnesses through modified Turmeric dyeing using rare earth salts as mordants, BTRA Scan, VolL No 4 page 6-9.

- Gangwar, A.and Vankar, P.S. (2022) Better dyeability in Natural dyeing of Silk using rare earth (RE) salts as mordant, BTRA Scan, VolLI No 2 page 4-9.

- Purwar, S. (2016) Application of natural dye on synthetic fabrics: a review. Int. J. Home Sci. Vol 2 No. 2, pp 283-287.