If you thought temperature specialist Outlast Technologies GmbH only offered functionally impressive heat-regulating and moisture-reducing textiles, you’d be mistaken. At the SLEEP Expo Middle East 2023 trade show, the company will present new materials, which stand out thanks to their eye-catching appearance and top-notch feel.

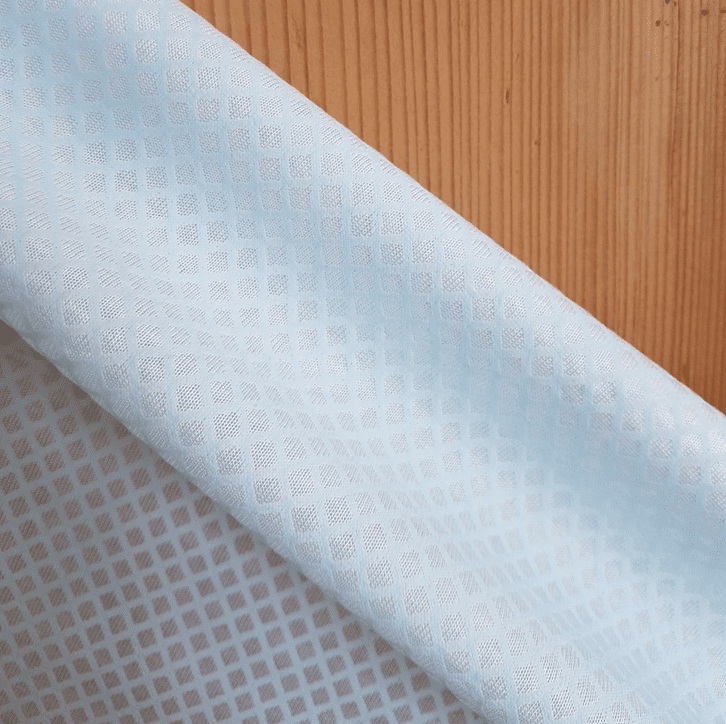

With the new “Ordway” product to be presented at SLEEP Expo Middle East, Outlast combines the tried-and-tested Outlast® Thermo-Technology coating with a thin 3D mesh. This not only bestows the product with wonderful elasticity and strong material thickness, but also an extremely pleasant, noticeably soft feel. Combined with features such as viscoelastic foam, this material ensures a quality, highly functional end product. Ordway is made in Germany, so it meets the highest quality demands as well as strict social and environmental standards during production.

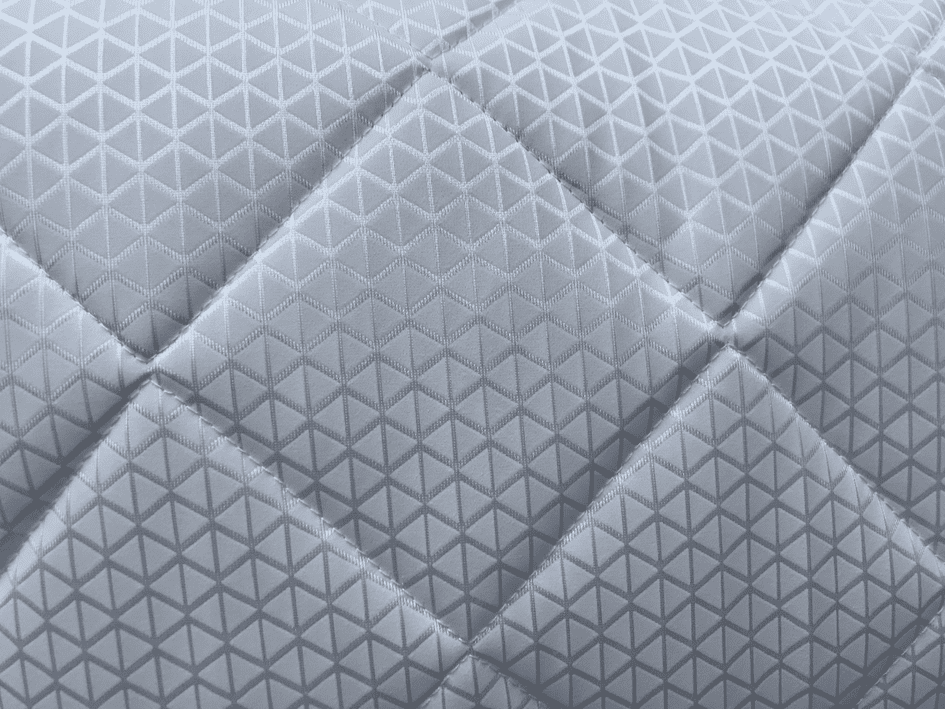

The “Grover” from Outlast is another eye-catcher at this year’s SLEEP Expo Middle East. The use of sparkling yarn lends this new item a strikingly beautiful, classy look. Without any use of silkworms whatsoever – and therefore the chemical residue often associated with them as well – Outlast offers these textiles with an elegant satin look. Despite its fine texture, “Grover” impresses with its high heat-absorption capacity, which reduces perspiration among sleepers and promotes good temperature regulation in bed, thus creating optimal conditions for deep sleep and nightly rest.

The new “Snyder” bedding item stands out thanks to its ultra-soft feel and fresh, appealing blue color. With this, the item also indirectly conveys the added value of the product, i.e. less sweating. With the help of natural materials, Outlast® bedding has the potential to reduce nighttime sweat production by up to 48%. The German-based Outlast development team not only uses natural wax as a buffer material for thermoregulation, but also utilizes Lyocell as the base material for the “Snyder” item. Lyocell is up to 80 percent cellulose (wood), a regenerative raw material. Lyocell also saves resources during production. The Lyocell production process requires up to 35 times less water than that of cotton. This means that Outlast is intentionally relying on regenerative raw materials and making a contribution to the sustainable use of finite resources.