Researchers at The Hong Kong Polytechnic University have developed a new class of soft, human-safe magnetorheological fibres that can flex, deform, and change mechanical properties under low-strength magnetic fields. Electrically driven and digitally programmable, these lightweight and breathable textile materials open new opportunities across smart wearables, soft robotics, virtual reality, and metaverse haptic applications.

Conventional magnetorheological materials rely on heavy magnetic powders and often require strong magnetic fields, which limits their suitability for wearable use. Led by Prof. Tao Xiaoming, the PolyU research team focused on transforming magnetorheological technology into fibre form while preserving essential textile qualities such as softness, flexibility, and air permeability.

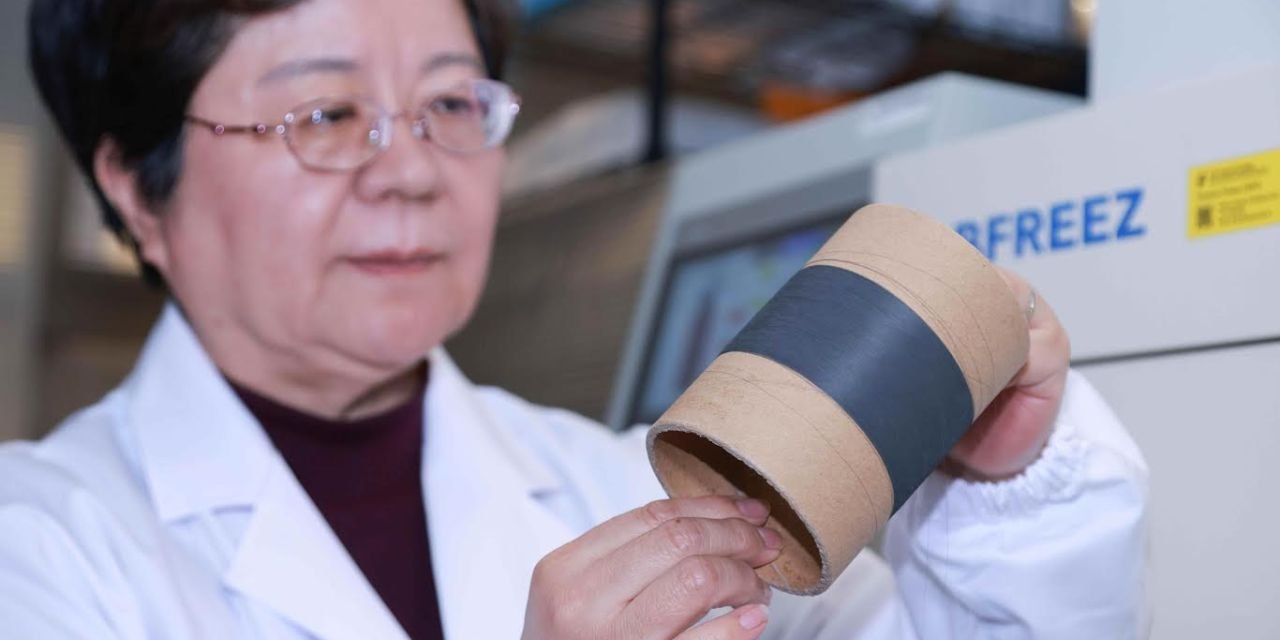

The team produced ultra-fine magnetic polymer composite fibres measuring just 57 micrometres in diameter by evenly dispersing magnetic powders within a low-density polyethylene matrix. These fibres respond precisely to weak magnetic fields, reduce material weight, and can be spun into yarns and layered fabrics to achieve controlled deformation across large surfaces.

Unlike traditional smart materials that react only to scalar stimuli such as temperature or voltage, the PolyU-developed textiles offer directionally controllable responses. This capability enables innovations such as flexible fabric-based grippers for handling delicate objects, lightweight haptic gloves that replicate texture and hardness for training and virtual applications, and active ventilation fabrics that adjust air permeability to improve thermal and moisture comfort.

The research, published in Nature under the title “Vector-Stimuli-Responsive Magnetorheological Fibrous Materials”, received HK$62.37 million in funding from the Research Grants Council’s 2024–25 Theme-based Research Scheme. Designed with scalability in mind, the materials use industry-ready raw inputs and processing methods, supporting future commercialisation in sectors including healthcare, food handling, rehabilitation, and immersive digital interaction.