Vibhuti Khedekar,

Assistant Professor,

Department of Textile and Fashion, College of Home Science,

Nirmala Niketan

&

Dr Ela Manoj Dedhia,

PhD Guide,

University of Mumbai

Director,

Anveshanam Foundation

SDC Trustee UK (Society of Dyers & Colorists)

Abstract

Khadi, a symbol of Indian heritage and sustainable craftsmanship, has evolved to embrace new blends and fiber innovations. This study explores the development and evaluation of two Khadi fabric compositions, Linen x Cotton (55:45) and Linen x Cotton (30:70) woven using traditional handloom methods. The aim is to assess their potential in contemporary sustainable fashion in terms of comfort, texture, drape, and aesthetic value. The study adopts a holistic approach involving yarn blending, fabric construction, and quality assessment. The findings reveal that both blends show promise, with the 30:70 blend exhibiting higher softness and breathability, while the 55:45 blend offers better structure and form. The results advocate for a balanced approach to fiber blending for diversified applications in modern textile design.

Khadi, once rooted in India’s freedom movement, is now evolving into a sustainable textile for modern fashion and lifestyle products. The study emphasizes that with the right fiber combinations, Khadi can transcend its traditional image and contribute meaningfully to eco-conscious fashion.

1. Introduction

Khadi has long been synonymous with India’s movement for self-reliance and sustainable textile production. In recent years, with the growing demand for eco-conscious fashion, there has been a renewed interest in reinventing Khadi with modern fiber blends while staying rooted in its artisanal techniques. Among the emerging sustainable fibers, linen, known for its strength, natural luster, and biodegradability, presents an excellent opportunity when blended with cotton, which is soft, breathable, and widely accepted.

Khadi is no longer confined to white cotton and traditional Indian silhouettes. As the global fashion industry shifts toward sustainability, Khadi presents a rare blend of heritage, ethics, and circular design potential. The fabric’s tactile charm and handcrafted identity make it highly relevant for designers looking to integrate authenticity and responsible production into their collections.

Linen, with its natural sheen and breathability, and cotton, known for its softness and versatility, together create blends that serve both functionality and fashion. When woven through traditional Khadi processes, these blends result in textiles that are not only eco-friendly but also visually and texturally appealing, capable of being shaped into both classic and contemporary garments.

2. Objectives

- To develop handwoven Khadi fabrics using two different Linen-Cotton blend ratios.

- To compare the aesthetic, tactile, and structural qualities of both blends.

3. Methodology

This research investigates two specific Khadi blends Linen x Cotton (55:45) and Linen x Cotton (30:70), to evaluate their suitability for sustainable fashion products. While both fiber blends are processed through traditional spinning and handloom weaving, their differing proportions offer varied characteristics that could influence end-use applications in garments and home textiles.

3.1 Materials and Methods

Fiber Selection and Yarn Preparation

Two Khadi blends were selected:

- Blend A: 55% Linen x 45% Cotton

- Blend B: 30% Linen x 70% Cotton

Khadi yarns were spun using traditional ambar charkhas. Cotton sourced was organic and locally available, while linen fibers were imported European-grade flax processed in India. The rovings of the fiber blends were prepared and spinning was done by trained artisans under KVIC guidelines.

3.2 Weaving Method

Handloom weaving was carried out using plain weave structure. Equal ends per inch (EPI) and picks per inch (PPI) were maintained for both samples to allow unbiased comparison. A simple loom with low-tension settings was used to preserve the natural texture of the yarns.

3.3 Testing Parameters

The fabrics were evaluated on the following parameters:

- GSM (Grams per Square Meter)

- Air permeability

- Tensile strength

- Fabric stiffness and drape coefficient

- Visual aesthetics and hand-feel

4. Results and Discussion

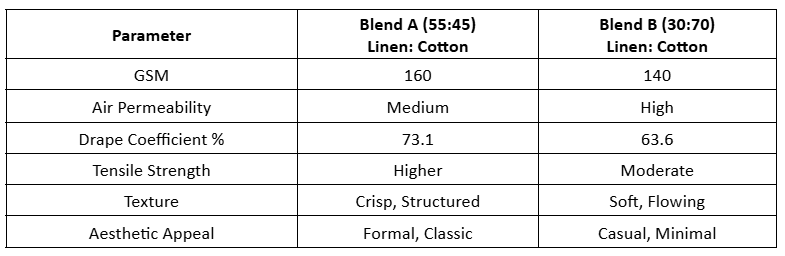

4.1 Fabric Weight (GSM)

Blend A showed a slightly higher GSM (160) compared to Blend B (140), indicating a denser and slightly heavier fabric. This makes Blend A more suitable for structured garments that require body, such as jackets or kurta shirts, whereas the lighter weight of Blend B makes it ideal for breathable, relaxed-fit summer wear.

4.2 Air Permeability

Blend B exhibited higher air permeability, contributing to enhanced breathability and wearer comfort. This can be attributed to the increased cotton content and looser fabric construction. In contrast, Blend A allowed moderate airflow, suitable for temperate climates or garments meant for transitional weather.

4.3 Drape Coefficient

Drape behavior, quantified as the drape coefficient, was found to be 73.1% for Blend A and 63.6% for Blend B. The higher percentage in Blend A indicates a stiffer drape with more structure, while Blend B, with its lower coefficient, had better flow and flexibility desirable for fluid silhouettes and casual clothing.

4.4 Tensile Strength

Blend A outperformed Blend B in tensile strength, primarily due to the higher proportion of linen, a fiber known for its mechanical strength. This makes Blend A more suitable for apparel requiring durability and shape retention. Blend B, while moderately strong, prioritizes comfort and softness over tensile resistance.

4.5 Texture and Hand Feel

Texturally, Blend A presented a crisp, slightly coarse surface with a structured feel reminiscent of traditional linen fabrics. Blend B, on the other hand, offered a smooth, soft, and supple touch, which enhances its comfort level for everyday garments.

4.6 Aesthetic and Design Relevance

From a design standpoint, Blend A was found to lend a formal and classic aesthetic, ideal for contemporary ethnic or semi-formal wear. In contrast, Blend B’s relaxed drape and soft texture offered a casual and minimalistic look, aligning with modern lifestyle and loungewear trends.

5. Sustainability Considerations

Both blends were created using hand-spun and handwoven methods, ensuring low energy consumption and zero industrial waste. Linen’s low water footprint and cotton’s biodegradable nature add to the ecological benefits. Furthermore, the production supported rural artisans and generated fair employment, aligning with the principles of sustainable development.

From a fashion sustainability lens, both blends excel in:

- Zero-machine weaving and low-energy yarn preparation

- Use of renewable, biodegradable fibers

- Support for rural artisan livelihoods

- Adaptability to slow, circular, and small-batch fashion models

Moreover, their ability to transition into elevated wardrobe staples from structured blazers to free-flowing skirts makes them viable alternatives to synthetic textiles in both ethical designer wear and artisanal fashion labels.

6. Conclusion

This research highlights the immense potential of Khadi Linen-Cotton blends as sustainable alternatives in the textile industry. Blend A (55:45) is structurally strong and suitable for occasion wear, while Blend B (30:70) offers superior comfort for daily wear. Both are eco-friendly, artisan-driven, and well-received by consumers and designers alike. This study affirms that Khadi can thrive in both fashion-forward and eco-conscious markets. Its story, spun on the charkha and shaped by skilled hands, continues to inspire a new generation of designers and wearers seeking style with substance. Future work may explore their performance post-finishing treatments such as natural dyeing and functional finishes.

References

- Das, K. (2020). Khadi: History, Ideology and Sustainability. Journal of Textile Development.

- Das, K. (2020). Khadi: Between Heritage and Innovation. Indian Textile Review.

- Fletcher, K. (2014). Sustainable Fashion and Textiles: Design Journeys. Routledge.

- Food and Agriculture Organization (FAO). (2022). The Linen Industry and Sustainability: A Global Perspective.

- Food and Agriculture Organization (FAO). (2022). Sustainable Linen Production and Environmental Benefits.

- Goswami, B. C., Martindale, J. G., & Scardino, F. L. (1977). Textile Yarns: Technology, Structure, and Applications. McGraw-Hill.

- Mehta, P., & Bhardwaj, S. (2017). Managing Quality in the Apparel Industry. New Age International.

- Shenai, V. A. (1981). Textile Fibers: Technology of Textile Processing. Bombay: Sevak Publications.

- Shenai, V. A. (1984). Textile Fibres: Technology of Processing. Bombay: Sevak Publications.

- Textile Committee India. (2023). Handloom Weaving Standards for Sustainable Development. Ministry of Textiles, Government of India.