In an era where fashion’s environmental footprint has become impossible to ignore, a quiet revolution has been unfolding in India’s textile landscape. For over a decade, designer, educator, and textile researcher Tasneem Merchant has been pioneering a comprehensive approach to sustainable fashion that bridges traditional craftsmanship with innovative waste management. This journey represents more than just an exploration of alternative fibres—it embodies a vision where eco-friendly fashion and sustainable livelihoods walk hand in hand, proving that environmental responsibility and economic prosperity need not be mutually exclusive.

The Banana Fibre Revolution: Turning Agricultural Waste into Textile Gold

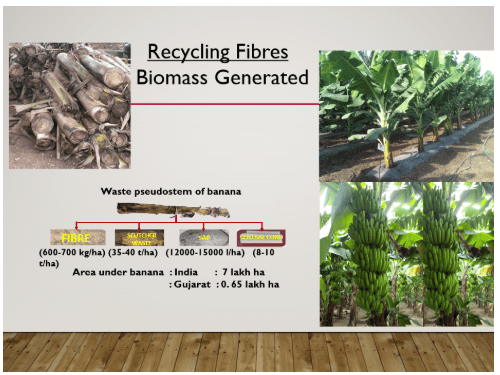

At the heart of this sustainable innovation lies an unlikely hero: the banana pseudostem. India, one of the world’s leading banana producers, cultivates this important fruit crop across approximately eight lakh hectares, with significant production in Maharashtra, Gujarat, Tamil Nadu, Andhra Pradesh, Karnataka, and Kerala. Yet for decades, what remained after harvest—the pseudostem—was simply discarded as agricultural waste, contributing to biomass accumulation and disposal challenges.

The transformation of this waste into valuable textile fibre represents a breakthrough in circular economy principles. Each hectare of banana cultivation generates substantial biomass: 600-700 kg of fibre, 35-40 tons of sap, 12,000-15,000 litres of scutcher waste, and 8-10 tons of central core material. What was once an environmental burden has become a treasure trove of resources, with each component finding purposeful application in the sustainable textile ecosystem.

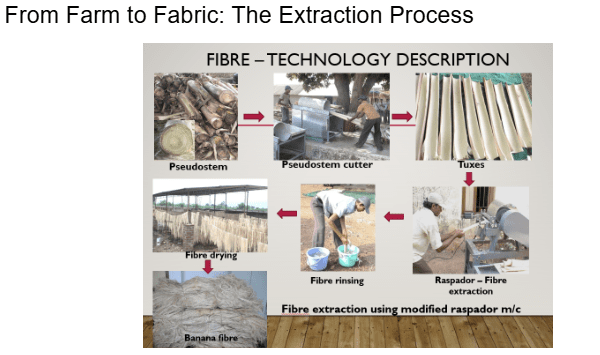

The journey from banana pseudostem to wearable fabric involves a carefully orchestrated process that combines traditional wisdom with modern technology. The extraction begins with a modified raspador machine, which processes the pseudostem through several critical stages. First, the pseudostem is cut using specialised cutters called tuxes. The raspador then extracts the fibres, which undergo thorough rinsing to remove impurities before being dried to achieve the desired quality for textile processing.

This technology description reveals the elegance of a truly zero-waste system. The scutcher waste finds new life as vermi-compost and paper, enriching soil health and supporting alternative industries. The sap extracted during processing serves dual purposes—as liquid fertiliser for agricultural applications and as a mordant in textile dyeing, eliminating the need for synthetic chemicals. Even the central core, often overlooked, can be processed into candy and other edible products, ensuring that virtually nothing goes to waste.

Economic and Environmental Impact: A Dual Victory

The adoption of banana fibre technology creates ripples of positive impact across multiple dimensions. For farmers, it represents additional monetary benefits beyond their primary crop yield, transforming waste disposal costs into revenue streams. The eco-friendly disposal of banana pseudostem addresses a significant environmental challenge while opening doors for employment generation in rural areas, where sustainable livelihood opportunities are often scarce.

The textile industry gains access to an alternative natural fibre suitable for technical textiles, reducing dependence on conventional materials with heavy environmental footprints. This convergence of economic and ecological benefits exemplifies how sustainable solutions can drive prosperity without compromising natural resources—a principle that forms the philosophical foundation of this entire initiative.

The Phoenix Charkha: Spinning Sustainability into Reality

The transformation of banana fibre into usable fabric presents unique technical challenges, particularly in managing the difference between filament fibres and short staple fibres. The Phoenix Charkha, a traditional spinning wheel, becomes the bridge between raw material and finished yarn. This skill-oriented process not only preserves traditional craftsmanship but also creates substantial employment opportunities—an estimated 2 lakh jobs in the spinning process alone.

The weaving process ingeniously combines innovation with tradition. Parallel sheets of cotton threads form the warp, while agro waste yarns—in both varieties—create the weft. This hybrid approach produces fabrics with a coarse texture and distinctive aesthetic appeal, offering designers and consumers textiles that tell a story of sustainability without compromising on visual impact.

Non-Woven Applications and Beyond

The versatility of banana fibres extends beyond traditional woven fabrics. As a cluster-based activity, non-woven fabric production offers proven technology with comparatively low investment requirements and easier management protocols. These non-woven applications unlock diverse possibilities: composite tiles using suitable resins, filler material for mattresses, sound-absorbing panels in auditoriums, heat barriers for extreme climates, and geo-textiles for construction and agricultural applications.

Fashion Forward: Sustainable Collections with Style

The practical application of these sustainable materials manifests in collections that refuse to compromise aesthetics for ethics. Handlooms, recycled silks, and textured banana-blended fabrics come together in print juxtapositions that create inherent style and elegance. Asymmetrical drapes weave landscapes of floating three-dimensional forms, while silhouettes inspired by gauze weave structures showcase how sustainable materials can drive innovative design.

From garments to home furnishings, these collections demonstrate that eco-fashion represents not a limitation but an expansion of creative possibilities. Sartorial cuts add vintage charm, while the natural variations in texture and appearance of alternative fibres create unique character in each piece.

A Decade of Global Recognition

Since the 2009 showcase at the International Conference on Natural Fibres and Technologies for Prosperity at the World Cotton Conference, this sustainable vision has gained global traction. Fashion shows across multiple platforms worldwide have commercialised the use of different banana pseudostem fibre blends, validating the market viability of sustainable textiles.

Building a Sustainable Future: Skills, Clusters, and Circular Economy

The vision extends beyond product creation to system transformation. Through skill development workshops, handloom clusters, and industry linkages, this initiative amplifies the circular economy model. It represents the culmination of two decades of research as a designer, educator, and research analyst, achieving a delicate balance between social equity and sustainable economic development.

This journey proves that roots need not be confined to landscape, country, or community—they exist within each individual committed to sustainable transformation. As humanitarian design strives to maximise existing capacities for economic and stylish adaptation, inspired by nomadic lifestyles and traditional wisdom, it charts a course toward prosperity that honours both people and planet.

The message is clear: sustainable fashion is not merely a trend but a fundamental shift in how we conceptualise design, production, and consumption. Those who dream of such transformation and commit to making it a reality will indeed learn to fly—carrying forward a legacy of innovation that proves environmental stewardship and economic vitality can flourish together.