Dr Ela Dedhia

Educator, Researcher, and Pioneer in Natural Dyes and Human-Centred

Textile Innovation

Dr Jinal Sangani

Dept of Apparel Manufacture and Design,

PVP, SNDT Women’s University

Introduction

Khadi isn’t just a fabric—it’s a living symbol of sustainability, craftsmanship, and cultural identity. Hand-spun and hand-woven from natural fibres such as cotton, silk, or wool, khadi offers a versatile textile that remains cool in summer and warm in winter.

Its eco-friendly nature stems from low energy consumption, minimal chemical usage, and biodegradable raw materials—making it a bona fide green fabric aligned with today’s environmental and ecological priorities.

Khadi also stands as a powerful engine for economic empowerment. Rooted in Mahatma Gandhi’s vision of self-reliance and rural upliftment, it provides vital livelihoods across India’s countryside

The fabric’s artisan-driven production sustains rural communities, and its expanding global appeal unlocks new avenues for employment and cultural exchange.

Integral to this ecosystem is the Khadi & Village Industries Commission (KVIC), the statutory body dedicated to revitalising khadi and rural industries. Since its inception in 1957, KVIC has been instrumental in planning, promoting, and facilitating khadi’s growth—supporting artisan training, market development, and sustainable industry practices.

In a world increasingly conscious of environmental impact, aesthetics, and ethical production, khadi has emerged as a global trend. From minimalist apparel to elegant home décor, its crisp texture and natural charm resonate deeply with modern sensibilities. With strategic enhancements in supply chains, retail infrastructure, and export frameworks, the khadi sector is poised for remarkable growth—fusing tradition with innovation and creating the “cloth of excellence” that KVIC envisions.

Purpose & Objective

UDYOG Bharti, being a well-known centre for khadi products, serves as an innovation hub for experimentation to meet consumer expectations. A study of this unit will give direction to the non-performing khadi centres.

- To study one of the centres of khadi doing well at the national level (Gondal, Gujarat)

- Explore the development of yarns and fabric at the Gondal centre.

- To study the effect of the implementation of experimentation with yarns, fabrics, and garment designs, made through the present study in the KVIC system, with respect to design development, marketing, and experimentation.

Review of Research

Research and development in Khadi, various Indian designers realised the potential of Khadi and its use; they started experimenting with this freedom cloth to give it a fashionable and glamorous look. Designer Devika Bhojwani pioneered the Swadeshi label of Khadi in 1985, which was distributed through nearly 5000 Khadi Emporia. This was the first step towards changing Khadi’s earlier image of being unfashionable. Some of such efforts are mentioned in the Table.

Indian designers taking such promising steps to make khadi a brand that not only inspires but also aspires the youth seem to be successful. Therefore, today, Khadi is attracting small upcoming fashion labels that are exploring possibilities to reinvent it. (Pradnya P. Ambreand and Sugandha Lad (2017), Khadi – Awareness and Promotion among Youth, International Research Journal of Engineering and Technology (IRJET))

Table 2.5: Efforts taken for the revival of Khadi

| Year | Endeavour for the Promotion of Khadi |

| 1985 | Swadeshi Label of Khadi by Designer Devika Bhojwani |

| 1989 | Fashion show by KVIC, displayed 85 dazzling khadi garments created by Devika Bhajwani |

| 1990 | Ritu Kumar presented her first Khadi Collection |

| Sept 2000 | Vasundhara Raje ( Minister then, for Small Scale Industries) initiated a movement to revive all 7000 shops of KVIC in India |

| May 2001 | KVIC set up their first air-conditioned shop in New Delhi |

| January 2002 | High-profile textile exhibition on khadi, designed by leading Indian fashion designers |

| October 2012 | Narendra Modi (then Chief Minister of Gujarat) appealed to all to buy khadi and promote khadi culture (Speaking on the eve of Mahatma Gandhi’s birth anniversary) |

| 2014-15 | Khadi production and sale grew by 6% |

| June 2015 | With the collective efforts of government, KVIC, and independent labels like Gaurang Shah, Sabyasachi, Fayakun, Red Sister Blue, Cotton Rack and many others started making khadi garments with a contemporary style, with international standards of quality |

| December2015 | Air India places an order worth INR 1.21 crore for their uniforms |

| January 2016 | Promotion of Khadi by Prime Minister of India, Narendra Modi, through ‘Man Ki Baat” |

| July 2016 | IIT Bombay placed the order of 3500 robes for their convocation ceremony, inculcating the feeling of Nationalism among students |

Source: Khadi – Awareness and Promotion among Youth, International Research Journal of Engineering and Technology (IRJET), 2017

Khadi presentation at different events like LAME, International SME Convention

Source: http://www.kvic.org.in/kvicres/index.php

The Solar Charkha Mission of the Ministry of Micro Small & Medium Enterprises (MSME) was launched by the President, Ram Nath Kovind, on June 27, 2018, in New Delhi. As per the report of the 4-year achievement of his Ministry, the Mission will cover 50 clusters, and every cluster will employ 400 to 2000 artisans. The Mission has been approved by the Government of India and will disburse a subsidy of Rs. 550 crore to the artisans. It was further informed by the Minister that 15 new state-of-the-art technology centres are being set up all over the country, including the North-East, of which 10 centres will become operational by March 2019. Each centre is being built at a cost of around Rs. 150 crore. The 10 centres which will become operational soon are located in Durg (Chhattisgarh), Bhiwadi (Rajasthan), Rohtak (Haryana), Visakhapatnam (Andhra Pradesh), Bengaluru (Karnataka), Sitarganj (Uttarakhand), Baddi (Himachal Pradesh), Bhopal (M.P.), Kanpur (U.P.) and Puducherry.

(Source: http://pib.nic.in/newsite/PrintRelease.aspx?relid=179921)

Artisan Wage Hikes and Incentives

- In 2018, KVIC approval for over 36% hike in wages for Khadi spinners: from ₹5.50 per hank to ₹7.50 per hank. YourStory.com+3ETRetail.com+3The Times of India+3

- Wage incentives under MMDA are transferred directly via bank accounts. Apparel Views+2MSME Ministry+2

Promotion and Market Growth

- Khadi sales have risen significantly: production numbers and turnover have trended upward. smeventure.com+2The Week+2

- Single-day sales records at certain Khadi outlets (e.g. Connaught Place, Delhi) have crossed ₹1 crore on many occasions since 2016. in-cai.in

- Government emphasising brand building (“Swadeshi”, “Made in India”), more visibility in exhibitions, e-commerce, etc. Upstox – Online Stock and Share Trading+1

KVIC Participation / Collaboration in Fashion Shows

| Year | Event / Show | Details |

| 2022 | “Aheli Khadi” / KVIC collaborates with NIFT (Gandhinagar) | Fashion show to promote Khadi fabrics — both traditional & contemporary styles via NIFT designers. KVIC collaborates with NIFT for fashion show to promote khadi – FashionNetwork India |

| 2018 | FDCI / KVIC – “Khadi – Transcending Boundaries” / SME Convention 2018 | FDCI presented a Khadi fashion show in collaboration with KVIC, with designers like Rohit Bal, Anju Modi, Payal Jain, Poonam Bhagat. Fdci Presented Fashion Show Khadi – Transcending Boundaries – Fashion Design Council of India |

| 2022 | Lakmé Fashion Week × FDCI — Sustainable Fashion Day | KVIC / Khadi India showcased Khadi ensembles by several designers, including an international designer (Mossi Traoré) and Indian designers like Anju Modi, Anavila, Rina Dhaka, etc. Khadi India / Kvic And Fdci Collaborate On Sustainable Fashion Day At Fdci X Lakmé Fashion Week – Fashion Design Council of India |

| 2019 | Lakmé Fashion Week Winter/Festive 2019 | KVIC collaborated with designers Gaurav Khanijo, Anuj Bhutani, and Pallavi Dhyani for a Khadi collection showcased during LFW. KVIC to collaborate with designers to showcase at Lakme Fashion Week – FashionNetwork India |

| 2023 | Lakmé Fashion Week X FDCI — Khadi India Collection | KVIC’s “Khadi India” brand showcased a collection with designers Divyam Mehta, Suket Dhir, and Shruti Sancheti. https://in.fashionnetwork.com/news/Khadi-india-to-showcase-collection-at-lakme-fashion-week-x-fdci%2C1493138.html?utm_source=chatgpt.com |

| 2025 | Khadi India show at Moscow Fashion Week | KVIC / Centre of Excellence for Khadi (CoEK) participated in Moscow Fashion Week under a collaboration with FDCI; designer Samant Chauhan presented a collection. Khadi: India’s finest product looks at global stage- The Week |

| 2023 | “Khadi Fashion Show” in White Rann of Kutch | A mega Khadi fashion show organised by KVIC in the Rann of Kutch; students from NIFT, Gandhinagar, participated, etc. ‘Khadi Fashion Show’ organized in White Rann of Kutch | DeshGujarat |

Methodology

Data Collection

To study one of the centres of Khadi doing well at the national level (Gondal, Gujarat). A visit to the Udyog Bharati Khadi Centre in Gujarat was planned in the months of November 2009, 2013 and February 2019. Centre infrastructure was documented; the staff was interviewed for data collection.

Methodology and techniques used for the production of yarns, fabric, and garments

Yarn production at the centre: Data generated through interviews of administrative staff revealed that readymade slivers are bought from KVIC-approved centres (cotton and polyester). Roving and drafting are done in-house at Amber Niketan.

The centre has separate setups for producing polycot and cotton.

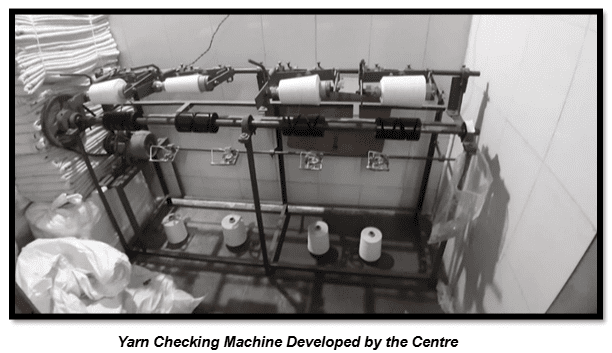

If any processing of the fabric is needed, like bleaching, scouring, wrinkle-free treatment, etc. is done at only the K.V.I.C. approved process house, i.e. B.M.P. process house in Ahmedabad. The Centre has developed its own Yarn checking/ improvement machine, which helps in maintaining the quality of yarns produced.

After yarns are produced, they are sent for finishing, like dyeing, which is outsourced either at Ahmedabad or Bagsara in Kutch. Dyeing is done in vat dyeing.

After yarns are processed, they are ready for the next stage, i.e. weaving. Looms used for weaving are leg-driven looms, and all of them are operated by women. These looms are used for higher speed and lesser yarn breakage.

The weaving unit is separate at the new Khadi Plaza. After the weaving fabric is sent for finishing processes like bleaching, dyeing, printing, etc., at Ahmedabad, Bagsara, and/or Kutch. Warping and sizing are done in-house.

Experimentation and Sampling

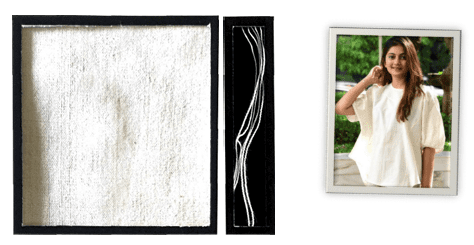

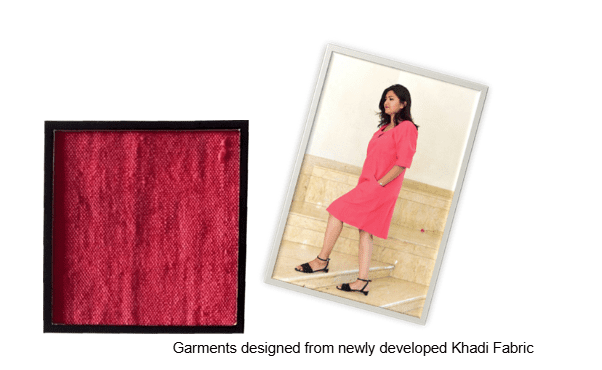

Fabric sample was developed by using cotton slub yarn, as can be seen in plate, sample-2. The texture was developed by using slub at a regular distance of 10 inches with 2 sets of yarns, one base and 2nd was a colour yarn twisted on it (one yarn of 100s count and one coloured yarn of 40s count). Fabric sample was developed in plain weave by using this yarn in the weft direction, and in the warp direction yarn used is cotton of 60s count

Garments designed from newly developed Khadi Fabric

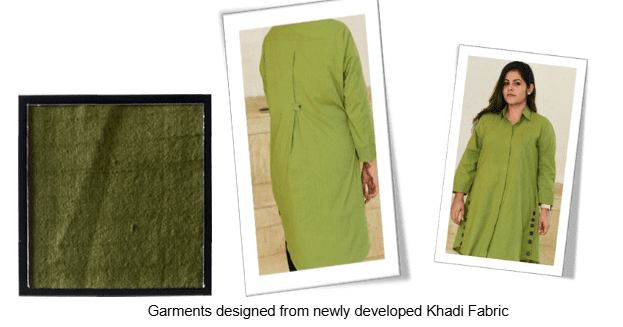

Development of the cotton Crepe yarn was done on a charkha. In this process, one yarn of s twist and other yarn of z twist were twisted together to make one yarn (25s count). Sample fabric was developed in plain weave by using these new yarns in the weft direction. In Warp direction, cotton yarn of 40s count.

Garment designed from newly developed Khadi Fabric

A fabric sample was developed using cotton and viscose yarns. Cotton yarns were used in warp direction (60s count) and cotton slub yarns (40s count) were used in weft direction, along with viscose yarns (30s count) at 1 cm distance in between. The fabric was developed in plain weave

As evidence in plate 3.2.B.9, the sample-9 fabric sample was developed by using a cotton and linen blend. 40’s count Yarns were developed by using Linen 30% and cotton 70%. Two 40’s count were twisted together and were used in warp direction and in weft direction. Fabric was developed using plain weave.

Consumer Evaluation for Developed Garments

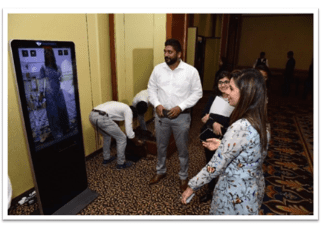

Once the garments were designed and produced from the developed samples and they were photographed and installed on the device called TRYON MAGIC MIRROR with 42 inches touch screen LED. It was a virtual dressing room which was installed during the Fashion Show, Chrysalis 2019 at the hotel The Leela’s on the 9th May’19. This virtual dressing room enables customers to visualise garments on themselves. This helps customers to virtually drape Digitised garments on themselves. To try out all the other garments, one simply needs to swipe the hand in front of the screen, and garments can be seen on oneself on the screen

Designing and styling of garments of the Khadi fabrics was done with the newly developed fabric. They were exhibited in a fashion show/ exhibitions/ stores, etc. and reviewed by consumers as well. The developed products were sold to generate revenue.

The garments designed were completely sold out.

Conclusion

The USP of the Gondal centre is the quality of the product they produce, price, fit, accessibility, and store layout. Three participants reported that trends and innovations were the USP of their facility.

Design institutes that helped the centre are Nirmala Niketan College, NID, and NIFT.

The Khadi textile industry contributes to the economic growth as well as the economic development of the country by providing a livelihood to the rural dwellers. If the Khadi industry is expanded and urbanised in the right direction, it can help provide a large volume of employment. It can raise the standard of living of people in the lower-income group, and can bring about more prosperity, as well as balanced economic development

The fabrics developed and the garments designed from newly created fabrics and their existing fabrics were done by keeping in mind the colour trend, and also by taking the youth’s tastes and preferences into consideration. Designs of the garment were based on the concept of anti-fit and minimalism. The patternmaking and designing of the garment were done according to the ongoing trend. Garments were designed with a concept which can be used as a unit or separates, or can also be combined with anything else, for example, a shift dress, a shirt dress, long tunics, pants, ¾ pants, etc. Designing the fabrics and garments according to the ongoing trend and liking of the consumers showed a really good result in the sales of the garments. The survey conducted for the same revealed that the majority of the respondents/consumers really liked the designs and the colour themes of the products and would definitely recommend them to others. So if production is done according to the study of the trend forecast, colour forecast and design forecast, the maximum audience can be captured and more revenue can be generated.

To attract a significant amount of youth towards their brand and products, understanding the trend of the market and then selling it on a digital platform can be of real help to the organisation to increase its sales and maintain a brand image. A Facebook page, an Instagram page and a website for the Gondal Khadi centre were created, which helped the centre in brand building and revenue generation. Also use of IT technology in inventory management was a success and of great help to the centre. Suggestions were also given on improvisation on their label designs, packaging materials, etc., to build a better brand image. The way other similar brands are undertaking the latest marketing strategies and tools, the same is required by Khadi to create brand awareness for Khadi products.

Scope For Further Research

There is a lot of further scope for fabric designing and garment designing in Khadi. Utilisation of modern but eco-friendly printing techniques for Khadi.

Use and development of eco-friendly surface ornamentation techniques to enhance fabrics as well as garments. Upgradation of technology and techniques of production.

Abstract

Khadi is a cloth woven by hand using hand spun yarn only. The objectives which the Father of the Nation “Gandhiji” had set for Khadi work, by and large, continue to be relevant even now. Khadi continues to be the main source of employment for the spinners and weavers throughout the country because they could not get an alternate source of employment at their doorsteps. The purpose of this research is to ascertain the status of Khadi use among a group of people, especially youth, including if they prefer or not to use it and why and to promote the use of Khadi and Khadi products in the retail market or ready-to-wear line in domestic as well as export markets by contemporizing Khadi without losing its identity. To develop products which are acceptable in the market or to develop products as per market demand, and also to study their acceptability, by conducting sales, exhibitions, etc. At present, there is a trend towards the use of natural products throughout the world. As Khadi production does not disturb our ecosystem, it is 100% eco-friendly. In modern Indian societies that are trying to urbanise rapidly and leapfrog into the high technology space, history education is being neglected. In such societies, Khadi would no longer be marketable with an emotional theme that would connect with India’s political movement centred around democratic freedom, independence and self-sufficiency. Therefore, a new approach has to be adopted to beckon the younger generation of consumers who wish to remain uninformed about India’s history and the great freedom struggle.

The objective of the study was to identify reasons for commercial success/challenges of Khadi and other organisations (Fab India) dealing with similar products as those of Khadi and village industry. And also to study the effect of implementation of experimentation with yarns, fabrics and garment designs, made through the present study in the KVIC system with respect to design development, marketing and experimentation.

The research methodology consisted of the administration of an interview schedule to collect pertinent data, documentation, design and product development, marketing and salability or consumer acceptance. It also includes helping the research centre with research and innovations, and developing brand identity globally.

For Khadi fabrics, it was observed that there is not much innovation in the production of yarns and fabric-making. As a course of development by using the centre’s existing technology, a few changes and alterations in the weft yarns were made even a few variations in weaves were also crafted. Further, quality inspection of the developed fabrics was done to check their esthetics, which according to the results, the quality was good for garment making. The fabrics developed and the garment designs of newly created fabrics and their existing fabrics were done by keeping in mind the colour trend, and also by taking the youth’s tastes and preferences into consideration. The patternmaking and designing of garments were according to the ongoing trend. Product development done during the study was appreciated by experts and consumers.

The survey conducted for the same revealed that the majority of the respondents/consumers really liked the designs and the colour themes of the products and would definitely recommend them to others. So if production is done according to the study of the trend forecast, colour forecast and design forecast, the maximum audience can be captured and more revenue can be generated.

They agreed that such measures of product development with proper promotional activity are necessary to ensure sales and sustainability. The result of the experimentation was positive.

To attract a significant amount of youth towards their brand and products, understanding the trend of the market and then selling it on a digital platform can be of real help to the organisation to increase its sales and maintain a brand image. A Facebook page, an Instagram page and a website for the Gondal Khadi centre were created, which helped the centre in brand building and revenue generation. Also use of IT technology in inventory management was a success and of great help to the centre.

If khadi fabrics/clothes are made with cutting-edge designs at par with global designs and brands, they will automatically appeal to the youth.