Textile sizing chemicals remain fundamental to modern fabric manufacturing, ensuring yarns can withstand the mechanical stress of weaving while delivering the required fabric finish, durability and surface quality. Applied primarily to cotton, polyester, nylon and blended yarns, sizing formulations create a protective film that minimises breakage, enhances loom efficiency and supports consistent fabric performance.

Functional Role in Manufacturing

Sizing acts as a temporary reinforcement layer on yarns, improving tensile strength, abrasion resistance and surface smoothness during weaving. Conventional formulations relied heavily on starches, natural gums and synthetic resins. However, the sector is now shifting towards advanced chemistries that balance performance with environmental responsibility, including water-based systems and biodegradable agents that reduce effluent load and worker exposure.

Key Areas of Innovation

Sustainable Formulations

Sustainability is now a central development driver. Bio-based polymers and biodegradable sizing agents are being engineered to lower water consumption, simplify desizing and reduce chemical residues. These solutions help mills meet stricter environmental norms while cutting processing costs.

Next-Generation Synthetic Polymers

High-performance synthetic polymers are offering improved fibre adhesion, elasticity and abrasion resistance. These can be customised for fibre-specific needs, enabling smoother weaving of high-speed looms and complex yarn constructions.

Nanotechnology Integration

Nano-enhanced sizing systems are enabling value-added yarn properties such as moisture management, antimicrobial performance and UV resistance. These are especially relevant in technical textiles, where functional performance is as critical as structural integrity.

Digital Process Control

Automation, sensors and data-driven controls are transforming sizing application. Real-time monitoring ensures optimal pick-up levels and uniform coating, improving efficiency, reducing wastage and enhancing reproducibility across batches.

Global Market Landscape

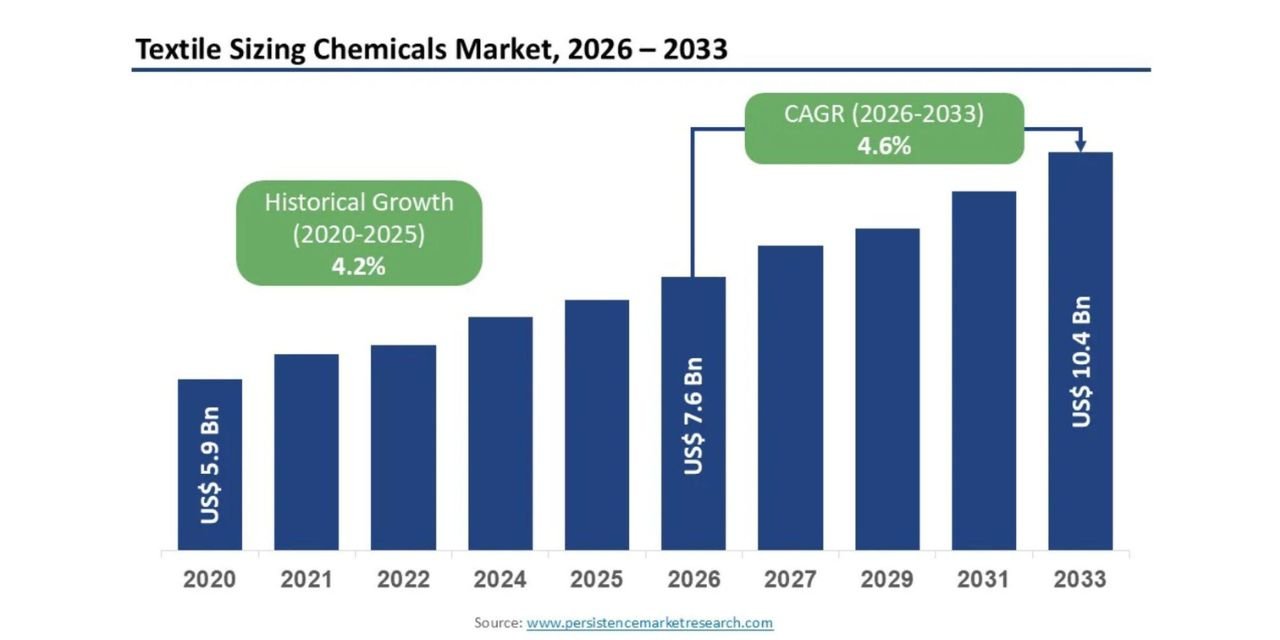

Demand for textile sizing chemicals continues to rise across apparel, home textiles and technical textile segments. Market research indicates the sector is projected to grow from approximately US$ 7.6 billion in 2026 to US$ 10.4 billion by 2033, reflecting a CAGR of around 4.6 percent. Growth is linked to the need for higher-quality fabrics, expansion in performance textiles and increasing compliance with sustainability benchmarks.

While apparel remains a major end-use segment, technical textiles are emerging as the fastest-growing area. Applications in automotive, medical, protective wear and industrial textiles require specialised sizing chemistries that deliver enhanced durability, functional performance and processing efficiency.

Future Outlook

The future of textile sizing chemicals lies at the intersection of sustainability, smart functionality and process optimisation. As environmental regulations tighten and smart textile development accelerates, demand will grow for low-impact, high-performance sizing technologies. The evolution of this segment underlines its strategic importance within the textile value chain, moving beyond basic yarn protection to becoming a contributor to advanced fabric functionality.