Dr Timble, DKTE

The fashion industry is constantly evolving, with new advancements in technology revolutionising the way garments are designed, produced, and consumed. From Product Design Automation to 3D Printing And Scanning, Robots, RFID Verification, and Recyclable Garments, let’s explore the latest innovations that are shaping the future of garment technology and manufacturing.

Product Design Automation

Product Design Automation is a game-changer in the fashion industry. It allows designers to capture and reuse engineering knowledge and intent, leading to more efficient and streamlined processes. By automating tedious and repetitive modelling tasks, errors are reduced, and time is saved. This technology can be scaled to streamline downstream development processes, ensuring faster production times and improved product quality.

3D Printing and Scanning

3D Scanning And Printing have transformed the way garments are created. 3D Scanning involves capturing physical objects and creating detailed, interactive digital models. On the other hand, 3D Printing allows the production of three-dimensional solid objects based on these digital models. This technology enables designers to create intricate and customised garments with unparalleled precision.

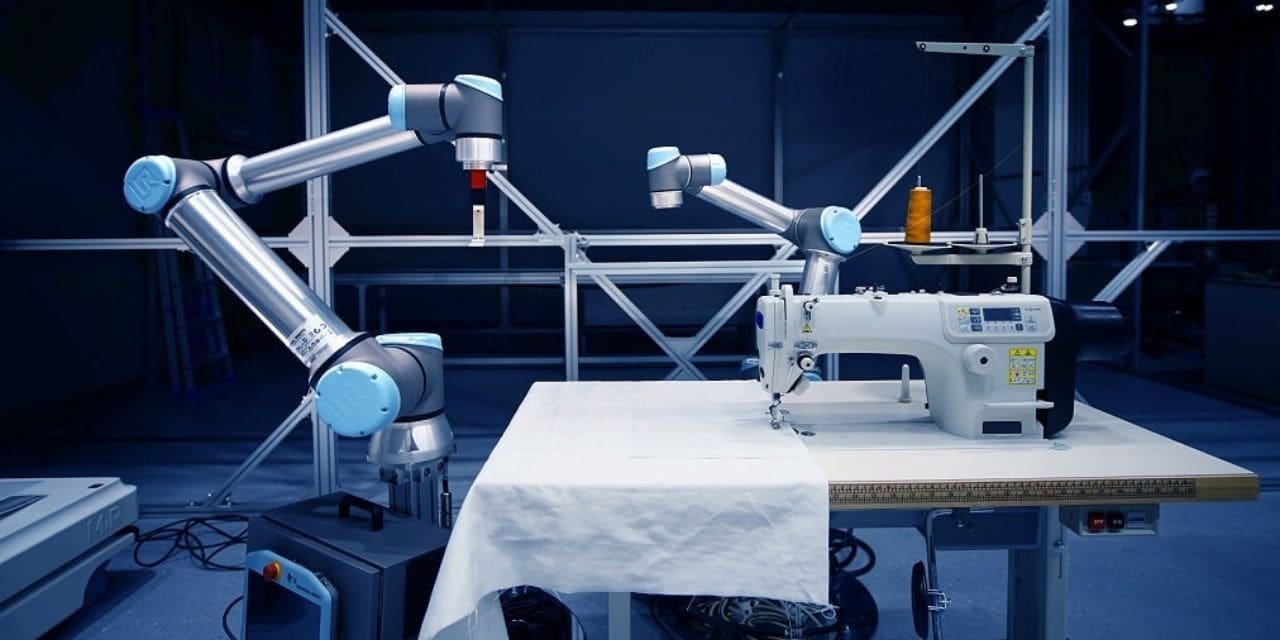

Robots

Robots have become a common sight on the factory floors of garment manufacturers. A robot is a programmable machine capable of completing tasks autonomously or under human supervision. The field of robotics focuses on developing robots and automation systems. Robots are used in various stages of garment manufacturing, including fabric cutting, sewing, and quality control. Their accuracy, speed, and efficiency have significantly improved production processes, leading to increased productivity and lower costs.

RFID Verification

Radio-Frequency Identification (RFID) is a technology that utilises radio waves to communicate a unique identifier between a tag embedded in an RFID card and an RFID reader. In garment manufacturing, RFID is used for verification purposes, such as verifying a user’s identity and granting access. RFID tags can be embedded in garments to track their movement throughout the supply chain, ensuring accurate inventory management and reducing losses. This technology enhances transparency and efficiency in garment manufacturing.

Recyclable Garments

Recycling in fashion, also known as textile recycling, has gained significant attention in recent years. It involves recovering existing fabrics, materials, or fibres to create new products. While manual textile recycling has been around since the 18th century, advancements in technology have allowed for more efficient and sustainable recycling processes. Innovative techniques, such as fibre identification and sorting, mechanical recycling, and chemical recycling, contribute to creating a circular economy in the fashion industry. Recyclable garments not only help reduce waste but also promote sustainability and environmental responsibility.

Conclusion

The latest innovations in garment technology and manufacturing are revolutionising the fashion industry. Product design automation, 3D printing and scanning, robots, RFID verification, and recyclable garments are transforming the way garments are designed, produced, and consumed. These advancements not only improve efficiency and quality but also contribute to sustainability and environmental responsibility. As technology continues to advance, we can expect further innovations that will shape the future of garment manufacturing and drive the industry forward.